8 3 Cummins Injection Pump Gear Torque

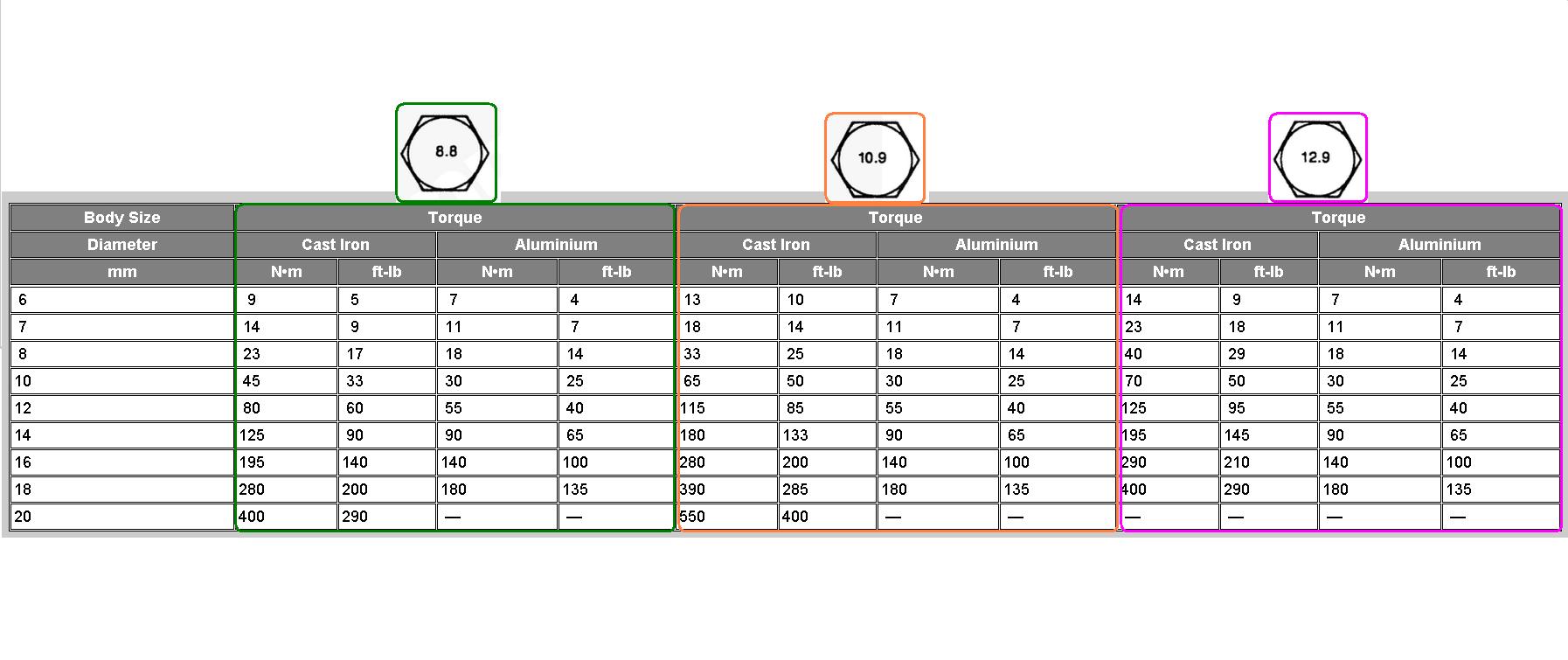

Damage to the timing pin do not exceed this torque.

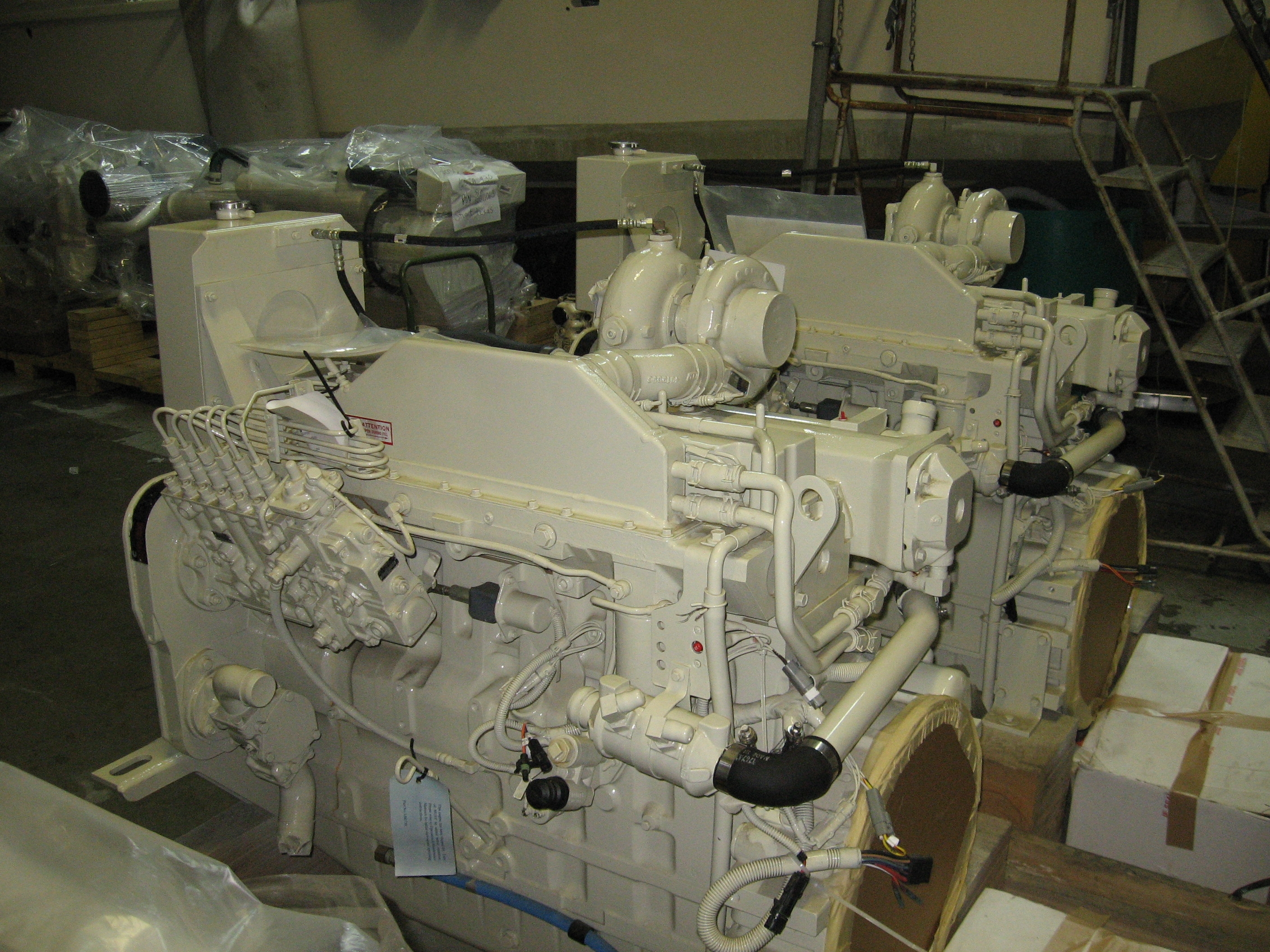

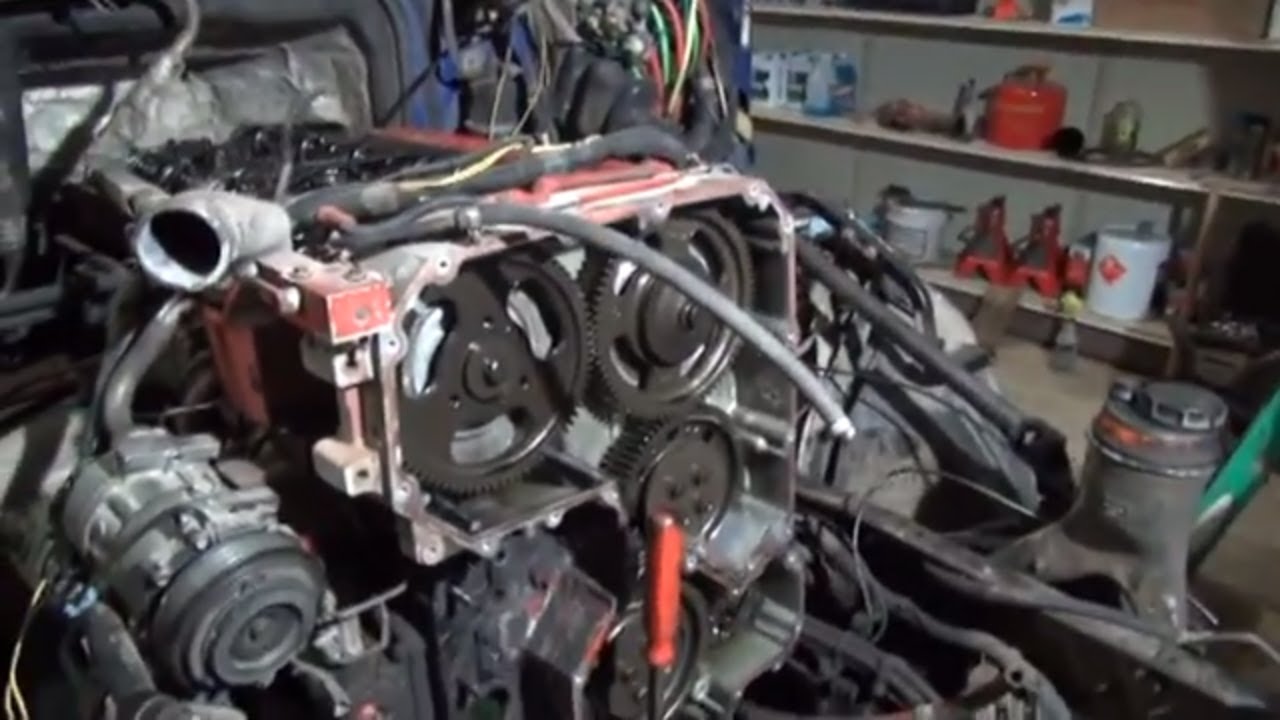

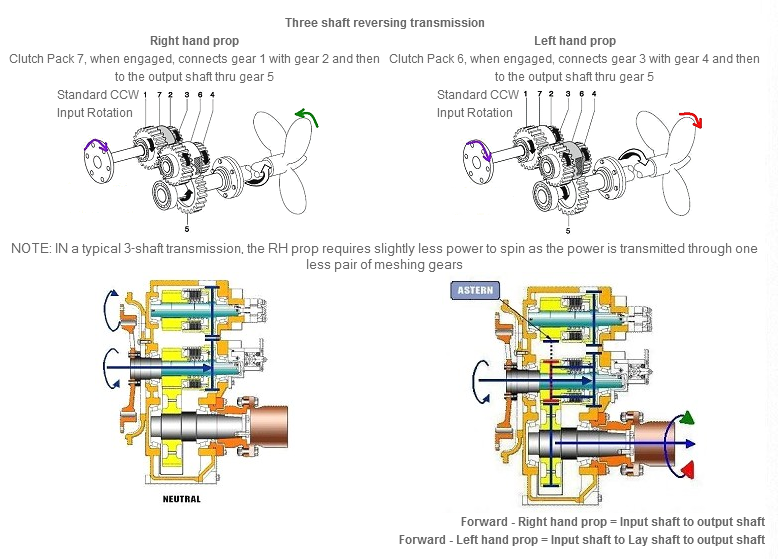

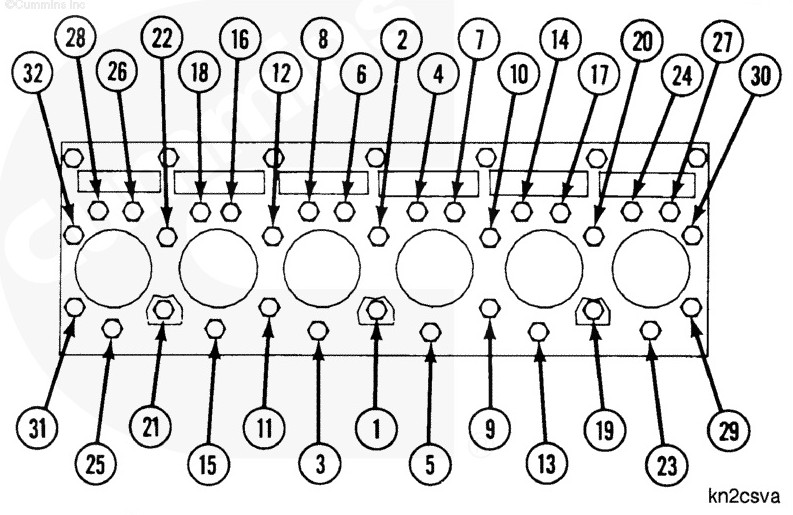

8 3 cummins injection pump gear torque. Disengage the timing pin from the rear of camshaft gear by pulling it straight back. 3 4 6 cylinder torque specs. Dr cummins and 87 other heavy equipment specialists are ready to help you. Fuel is forced through the fuel filter ele ment and then enters the fuel pump gear pump which is attached to the rear of the fuel injection pump.

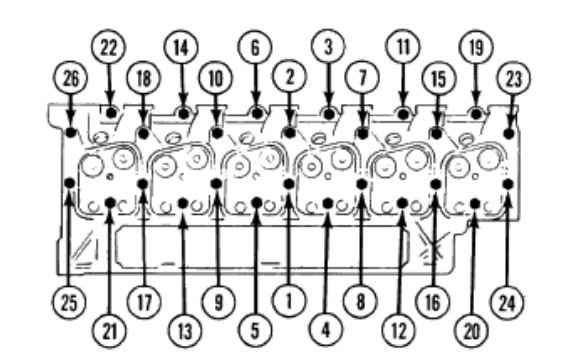

180 n m 132 ft lb dr cummins field service technician. Do a final tightening of the injection pump gear to injection pump shaft nut. Isc caps troubleshooting assistance. The fuel pump gear pump is a low pressure pump and produce pressures ranging from 551 5 kpa 80 psi to 1241 kpa 180 psi.

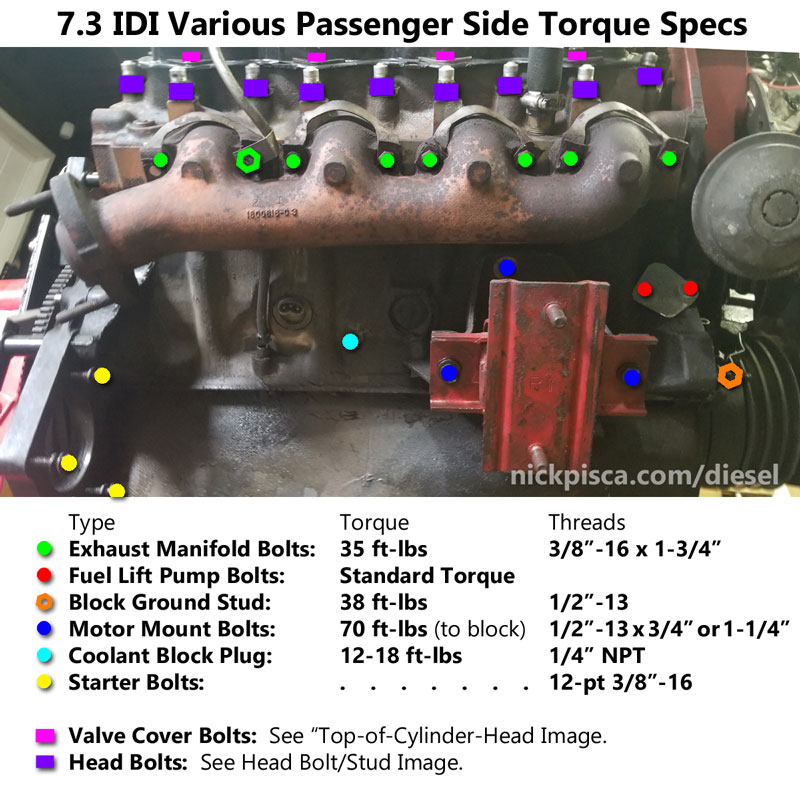

106 in lb make sure the timing pin in the gear housing is disengaged from the cam and the pin in the pimp is reversed and the slotted side is not in the cap and the brass pin is in the pump torque to 140ftlbs as the final torque on the nut the fuel pump mount nuts are 35 ftlbs. Ask your own question now. Cummins service engineering has compiled a short bulletin containing troubleshooting tips and other helpful information to assist the technician working on isc engines. D icv distributor module.

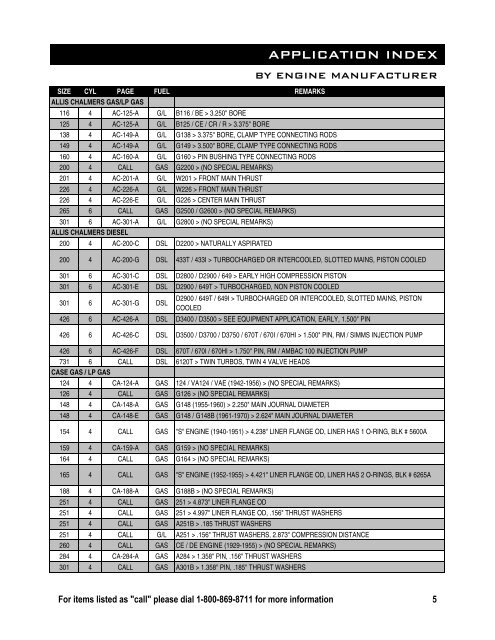

Parts catalog alphabetical index. E rate shape tube. Home injection pump gear nut torque cummins marine diesel repower specialists forums cummins marine engines injection pump gear nut torque this topic has 0 replies 1 voice and was last updated 13 hours ago by aarb612. 16 years working on cummins diesel engines verified.

Fuel then enters the fuel injection pump. Cummins accumulator pump system caps fuel pump. Remove the access plug from injection pump and remove timing pin tool from pump. Il 71 series general information.

2 cylinder torque specs. Fuel injection pump. Tighten the fuel injection pump drive gear nut. Liner block guide.

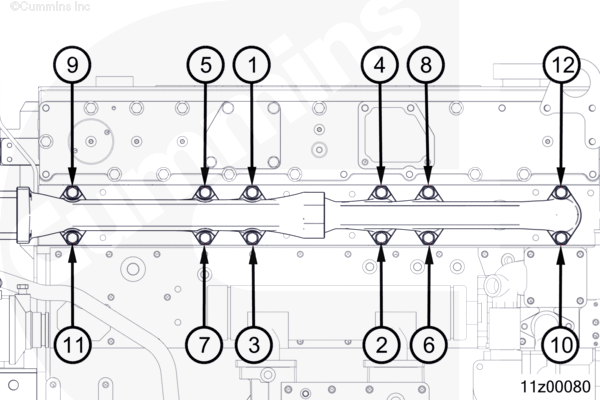

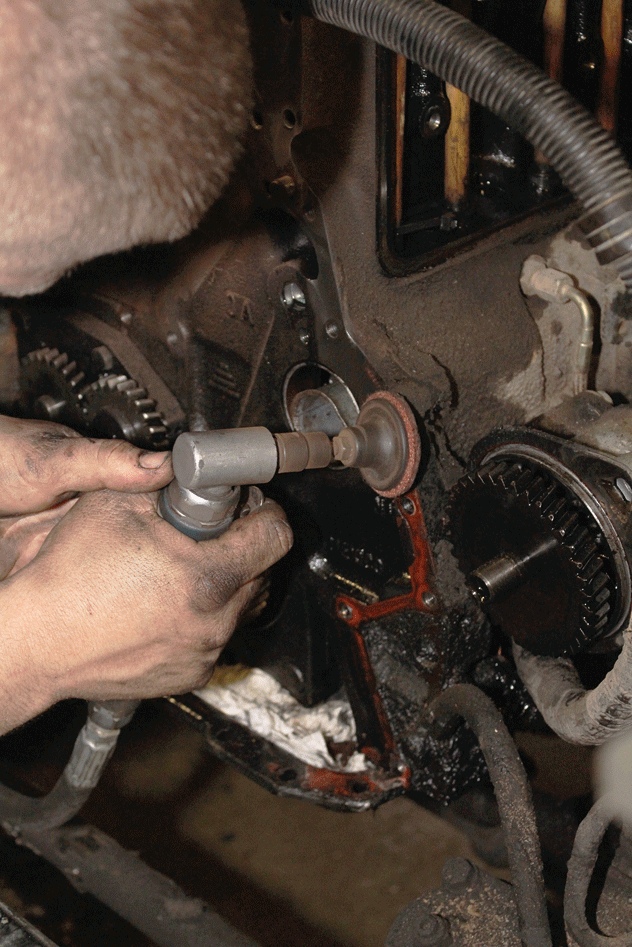

Timing pin location 8. This bulletin should. Parts catalog group index. We continued moving the pump to 6 8mm of lift or approximately 18 degrees before pinning the pump with the plastic pin shown in the third photo and then pulling the injection pump gear with a gear puller.

Ecm dataplate qsc8 3 and qsl9 engine identification section e engine and system identification page e 3 ecm dataplate the ecm dataplate is located on the front of the ecm. A barring tool was used to secure the engine in place so the timing pin wouldn t break when the gear was broken loose. Low pressure fuel is then sup plied to the fac fuel control actuator. Tighten to 165 nm 122 ft lb torque.

Inline 71 series information.